ZOZEN condensing gas-fired boiler system escorts Shanghai Flower Port

At present, artificial intelligence (AI) and the Internet of Things (IoT) have been increasingly applied to various fields. ZOZEN has always adhered to technological innovation, and has continued to explore the application of artificial intelligence and Internet of Things.

ZOZEN actively embraces new opportunities of AI and IoT technology

Currently, AI technology is mainly used in the combustion optimization of boilers. ZOZEN concentrates on the combustion characteristics of boilers in China. By detecting the important parameters of boiler combustion and the combustion optimization control system on-line, ZOZEN not only improves the overall thermal efficiency of ZOZEN boilers, but also reduces the NOx emissions in boiler flue gas as low as 30mg/Nm³.

AI helps ZOZEN effectively improve combustion efficiency and reduce pollution

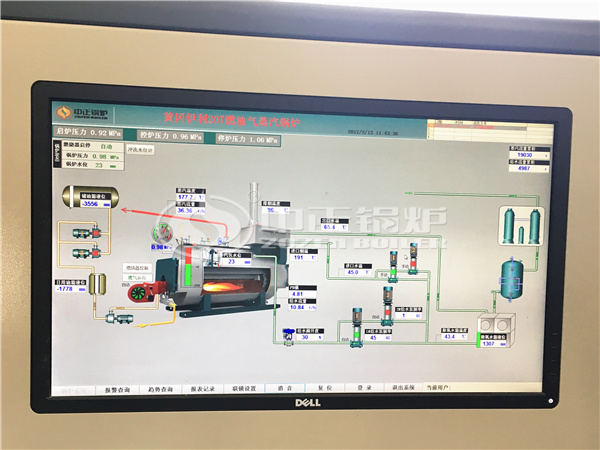

In the application of the IoT technology, the PLC control system of ZOZEN is the brain of the whole boiler system. When the automatic function is turning on, the controller can automatically control the system according to the mode set by the user on the basis of the scene signal collected by the system, which provides a solid guarantee for the safe production of many enterprises. Meanwhile, PLC boiler control system is very popular among engineers and technicians with its simple and easy to operate features.

The operation interface of ZOZEN PLC control system

ZOZEN assists Shanghai Flower Port to complete alternative clean energy project

Shanghai Flower Port is a modern agricultural demonstration park engaged in flower planting, new product R&D and germchit export. The flowers are very delicate and have high requirements for temperature and humidity. The boiler is very important in ensuring the constant temperature and humidity of the flower greenhouse.

Shanghai Flower Port took the lead in launching an alternative clean energy project, and it was urgent to introduce environmentally friendly boilers that used natural gas as fuel. With its own technical advantages and excellent quality, ZOZEN became the boiler supplier of the No. 2 boiler room of Shanghai Flower Port. ZOZEN customized the complete boiler system including a branch of WNS series gas-fired hot water boilers and steam boilers.

ZOZEN WNS series gas-fired boilers for Shanghai Flower Port

Based on the environmental protection requirements of Shanghai Flower Port, ZOZEN not only adopted intelligent clean combustion technology, but also selected advanced low NOx burners. ZOZEN also added energy-saving devices such as condensers at the tail of the boilers.

ZOZEN applied the IoT technology to the boiler control system, so that the boiler operator of Shanghai Flower Port can realize the functions of system start-stop, parameter setting, data query, etc. through the simple and clear control system operation interface. Analysis of the situation, performing an analysis of boiler operating conditions. In addition, over ten kinds of safety auxiliary systems, such as boiler water level safety device and combustion interlock protection, ensure the fully automatic and safe operation of the boiler and realize intelligent control.

AI and the IoT will provide more possibilities for improving boiler combustion efficiency and reducing pollution emissions. In the future, ZOZEN will grasp the new trend of technology and realize the deep integration of industrial boiler manufacturing with AI and IoT.

- Previous 2019-11-03 08:00:00 ZOZEN always pursues the perfection of details to the utmos

- Next 2019-11-03 08:00:00 ZOZEN successfully passed the fourth ASME certificate renewa