How are palm shell and fiber used as biomass fuel?

Palm oil is a tropical vegetable oil, it has the largest capacity, consumption and international trading amount in the world. Palm oil, soybean and rapeseed are 3 main vegetables in the world. Indonesia, Malaysia and Nigeria are the biggest suppliers of palm oil.

During manufacturing of palm oil, from the raw material cooking, crude oil treatment and refinery including decolor and deodorization, many sections needs heating or evaporating, so a huge amount of steam is consumed. Palm shell and palm fiber (EFB fiber) can be sent to boiler as the fuel of biomass-fired boiler, generating steam for process equipment. In this case the plant can save cost and deal with solid waste. So how are they used as fuel burning in boilers?

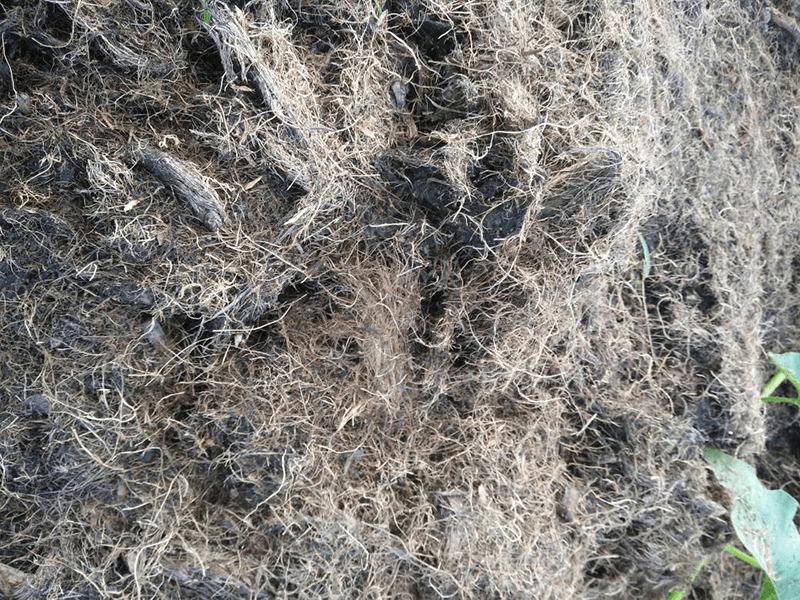

After palm shell is grinded and dried, its particles (Pic.1) can be already burnt as a good quality biomass fuel for biomass-fired boiler, the thermal value is around 4000Kcal/Kg. But palm fiber (EFB) fiber is similar with hair (Pic.2), it has below disadvantages during combustion:

1. Low density and thermal value, big feeding space is needed, which will cause low feeding temperature and uncompleted combustion.

2. Irregular fiber is easy to be stuck at feeding inlet and make defects, which affect feeding and combustion efficiency.

3. Fine fiber is easy coking and stick to the grate and damage grate.

To avoid such faults, palm fiber (EFB fiber) can be grinded and pressed into particles by pelletizer. (Pic.3)

SENTURY, as a customer of ZOZEN in Thailand, they burnt palm shell as fuel, and make palm fiber into particles, increased the thermal value and combustion efficiency of the biomass-fired boiler.

- Previous 2019-10-07 08:00:00 ZOZEN gas-fired water-tube boiler is shipping to Turkmenista

- Next 2019-10-07 08:00:00